Since the iPhone 4 series has successfully entered the Chinese market. In recent years, whenever Apple releases a new iPhone, iPhone packaging will attract great attention.

And even every iPhone packaging is full of topics. Apple’s design considerations are not just for products. In the packaging box of the iPhone series, there are also exquisite skills that other companies cannot catch up with.

22 nm technology is the highest level of domestic satellite navigation chips at present;

21 seconds is the perfect docking between change-5 and the lunar orbit;

0.000102 carat is the craftsmen’s leanest cut diamond from;

6 seconds is the ultimate requirement of iPhone packaging technology

01

iPhone 3g/3gs of iPhone packaging box

iPhone 3g/3gs packaging box is black and white. Packaging materials mainly come from recycled fiberboard and biological materials.

The packaging size reduced from 2.75 inches to 2.25 inches. The packaging adopts an embossed design. The height of the iPhone is slightly higher than the packaging, and the part of the home key adopts a concave design.

02

iPhone 4/4s of iPhone packaging box

The color of the iPhone 4 series packaging box is white, and the material is cardboard + coated paper. As the iPhone 4 is the generation that has made the biggest changes in appearance, with a glass and metal middle frame.

Apple uses a half-length, about 45°on the packaging to highlight its design and lightness. iPhone 4S packaging is the same as iPhone 4, and there is basically no design change.

03

iPhone 5/5c/5s of iPhone packaging box

iPhone 5 series packaging box is divided into black and white, and the material is cardboard + coated paper. The graphic design of the iPhone 5 decorative paper returns to a more direct full-body photo close to 90°.

The product also includes Apple’s AirPods headset, redesigned headset, and a lightning USB adapter. The packaging of the iPhone 5S is similar to the overall design of the iPhone 5.

The iPhone 5C packaging box is polycarbonate plastic with a white base and a transparent cover, which continues the simplicity of the past.

04

iPhone 6/6 plus/6s/6s plus of iPhone packaging box

The iPhone 6/6s/6s plus packaging box is a skinned carton. According to the color of the phone, the box is also black and white. The icon of music has become music, and the embossed design has returned on the iPhone 6/6 Plus, with the packaging being extremely simple.

05

iPhone 7/7 plus of iPhone packaging box

When it comes to the iPhone 7 series, the packaging box design adopts the appearance of the back of the phone, and only the words iPhone are on the side, without the Apple logo.

06

iPhone 8/8 plus of iPhone packaging box

The packaging box of the iPhone 8 is on the back, also a trace of glass reflective light. Showing that iPhone 8 is double-sides glass, and there is only iPhone on the side.

07

iPhone X of iPhone packaging Box

The packaging of the iPhone X series focuses on the design of a comprehensive screen. A large screen is on the front, which is very visually shocking, and on the side is still iPhone. Then in 2018, the iPhone XR/XS/XS Max also followed the packaging design of the iPhone X.

08

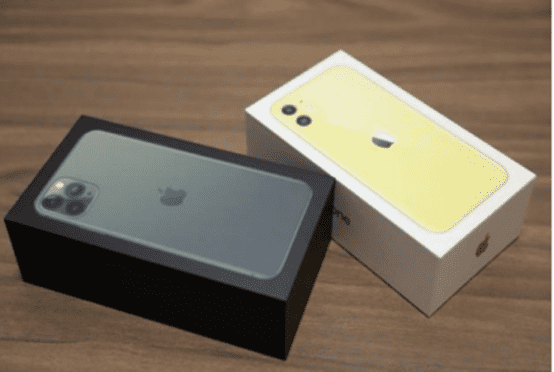

iPhone 11/11 Pro/11 Pro Max

iPhone 12/12 pro/12 Pro Max box

The packaging boxes of the iPhone 11 and 12 series have basically not changed much, but since they are no longer contain headphones and chargers, you can see from the side that the box has become much shorter.

iPhone 12/12 pro/12 Pro Max box

09

iPhone 13/13 pro/13 Pro Max of iPhone packaging box

For the iPhone 13 series released in September this year, the plastic film will no longer use in the packaging box, which Apple said will reduce the use of about 600 tons of plastic. Instead, there is a note similar to the express document bag.

The new paper tear pull design can open with just a gentle pull. And this paper seal is difficult to restore, which not only protects the environment and saves costs, but also avoids the possibility of secondary packaging fraud.

Technological differences between iPhone packaging and ordinary packaging

The mobile phone packaging box is basically based on the heaven and earth cover box. It is not only cost controllable, but also more convenient for consumers to operate.

The iPhone box also chooses the heaven and earth cover box, but it has a unique design compared with the ordinary heaven and earth cover on the market.

Apple requires that when all outer boxes are picked up, the lower part can slide down at a uniform speed of 1.5 cm, and the error rate of the sliding speed and distance cannot exceed 3%.

From the opening of the upper cover to the landing of the lower cover, it is often as long as 6 seconds.

This not only facilitates the user to open the box but also protects the containing machine from accidental injury.

This just right damping reflects the strictness of the quality requirements of the Apple mobile phone box in processing and manufacturing.

Today, the 6-second slide process has attracted the industry to follow up, and gradually evolved into the new standard of Top And Base boxes.

And the standard packaging of high-end digital products. This puts forward higher requirements for the packaging and manufacturing process of the Top And Base boxes.

Such as, the gap between the inner box and the outer box should be controlled at 0.5 mm. The clearance is too small, the air cannot be discharged, and the sliding is blocked.

The gap is too large, and there is no friction between the cover and the bottom box, so the effect of natural sliding in 6 seconds cannot be achieved.

Details reveal the mystery of iPhone box

Compared with the “plug-in carton” which can be folded with only one piece of thick paper and corrugated paper, this kind of carton is more rigid and has higher precision.

Moreover, by changing the decorative paper pasted on the surface, the texture and the impression of the packaging box can be adjusted freely.

The packaging of high-end brands at home and abroad such as cakes and jewelry for gifts mostly uses the leather carton.

However, due to the limitations of mechanical automation production, the cost of laminated cartons is high, and because of structural reasons, there are some limitations and characteristics in the manufacture of cartons.

In the traditional manufacturing process, the gray board of the gift box is formed as a whole, and the side and end faces are fixed with adhesive film.

The apple packaging box adopts the scheme of splicing two pieces of cardboard on the end face, which perfectly avoids the traces of sticking feet, and realizes the box body is as smooth as “cut tofu pieces in one go”.

Apple not only adopts the V-groove process for paperboard but also has unprecedented V-groove treatment for facial paper.

The box made in this way has sharp edges and corners, has strong rigidity and sexiness, and conveys Apple’s “uncompromising” design and quality concept to consumers.

For this reason, Apple has made simple and strong packaging based on V-shaped cutting technology and through multiple improvements.

Strict requirements of iPhone packaging

In order to make the edges and corners clear, Apple’s “iPhone” series packaging box adopts the high-cost “V-CUT” method for the backing cardboard. And the real innovation Apple has set off in the packaging is actually the decorative paper wrapped outside the core board.

The packaging box of the Apple mobile phone has particularly strict requirements for equipment. In the processing process, the paper will stretch if it is not paid attention to slightly, which will not only greatly affect the accuracy, but also cause curling and bending.

At the same time, the temperature and humidity management, the flattening technology after pasting, and the need to maintain the best state at all times in each process almost represent the most stringent standards in the packaging industry.

With aluminum processing as the center, Apple has brought a lot of new atmosphere to the manufacturing industry, and in the field of cardboard boxes, the company has also set off a revolution.

A small packaging box shows the concept of apple as a company. Apple is not only a master in product packaging design but also a master in product packaging design, which is worth studying and learning.

What do you think of the apple box?

If you are interested in the different styles of windows, please leave me a message below.

Email: sales02@huiyougroup.cn